PHILOSOPHY

ORIGIN OF COMPANY NAME

Mutsubishi Rubber Co., Ltd. was established in 1922 by six founders. They imagined concentrating of six diamonds, each of them have valuable technological capabilities. Therefore, they determined to use “Hexa” for a brand name, six diamonds for company emblem and translation of Hexa-Diamond as Mutsubishi which we use our company name.

QUALITY & ENVIRONMENTAL POLICY

Toward quality

Set primary goal of “Customer Satisfaction”, performance and manufacturing of our products fulfill customer’s requirements and expectations and prevent nonconformity at any stage of execution from designing to delivery of products.

Supply excellent Quality, Delivery, Cost, Safety and Security products, to gain customer’s trust and contribute to society.

Toward environment

Aim at earth-friendly company, work on environmental efforts and pursue better environment, contribute to society throughout corporate activities.

Fulfill customer’s quality requirement, understand and recognize importance of environmental matter by all employee, continuously improve effectiveness of Quality and Environmental management system of corporate activity, improve customer’s satisfaction, collaborate and harmonious coexistence with community, and aim at contribute to society.

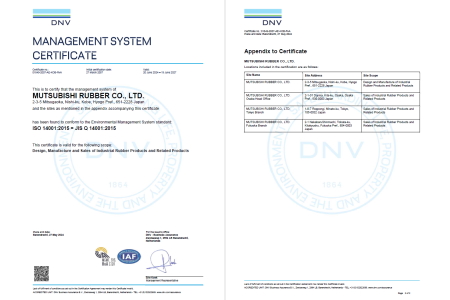

Certified company

In 2004, Kobe factory authorized “from Kobe and excellent technology” from Kobe-shi industrial promotion foundation. Our compounding technique of sticker material for industry and a rubber for a special purpose “and” development could be admitted.

PRODUCTION & MANAGEMENT SYSTEM

Manufacturing Control Flow

-

Raw material acceptance

- Product Design

- Materials Research

- Raw material acceptance (Acceptance test)

-

Combination

- Weighing control

- Creating a Combination List

- Combination

-

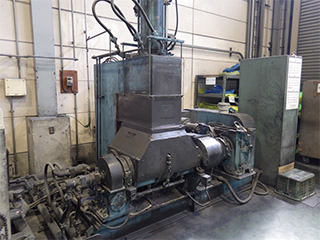

Mixing

- Mixing (Implementation of material testing)

-

-

Vulcanization molding

- Mold Management

- Pre-molding, Dimension and mass control

- Temperature and time control

- Vulcanization molding

-

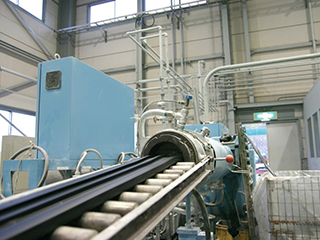

Extrusion molding

- Mold Management

- Extrusion molding

-

-

Finishing

- Finishing prosess

-

Product Inspection

- Product Inspection (Final Inspection)

-

Product Shipment

- Product Shipment